By Tom Ullmer

At Matrix, “good enough” is not in our vocabulary. Our engineers are consistently working to find solutions that improve our capabilities for customers across all industries. The MVC-300L is the latest example of that commitment, blending the proven quality of an existing machine with an innovative new module to optimize packaging liquid products.

The Quality You Know

The MVC line is one of Matrix’s most trusted product groups. This catalog of continuous motion vertical form fill seal machines offers a variety of size options and features to create a solution tailored to applications in snack, frozen foods, produce, cheese, and more. No matter the individual design elements a customer includes in their MVC machine, they can be confident in its successful history of elevating packaging lines.

The Innovation You Asked For

Nothing was stopping customers from using the existing MVC line to package liquid products. Every unit in the line can reliably handle and seal liquids. However, there was room to further optimize the machines for liquid-specific applications.

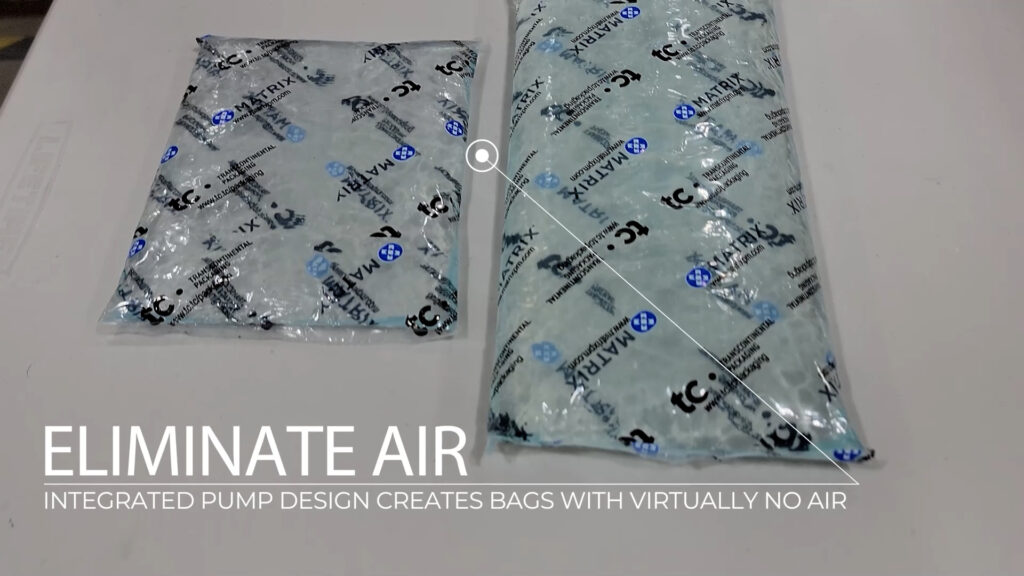

Shelf life is the primary concern for all perishable food packaging, and one of the best strategies to preserve the shelf life of liquid products is to remove the air in the bag. In the existing MVC line, this was partially accomplished. When the bag was closed, air was squeezed out before the top was sealed. While this removed some of the air, it did not get it all. This could be seen in packages laid flat on a table or other surface, as they would still have an air bubble in the bag.

With its newly invented pressurized roller system, the MVC-300L prevents air from entering the bag in the first place. As pouches are formed, the machine holds a column of the liquid product above the roller as a reservoir. When the rollers are opened, nothing but liquid can go through, and the bag is sealed before air can enter. Holding the bag vertically will still leave space between the liquid and the top of the bag to make a clean seal, but when the container is laid flat, there is no air bubble at all.

The Applications You Need

The product preservation benefits of this new module make it an ideal option for any liquid packaging in the food industry. Dairy, beverages, sauces, and other liquids can run through this machine, as well as products like soups that contain a mixture of solids and liquids. Products are usually packed in polyethylene bags with varied thickness depending on the needs of the application. Customers often have a wide range of bag sizes and film characteristics that the MVC-300L is optimally designed to handle. Additionally, case packing is easier when air is removed from bags.

Like the rest of the MVC line, the MVC-300L offers the flexibility to elevate all kinds of applications. By adding the roller module and integrated liquid pump, the MVC-300L provides customers with history they can trust and an innovation that puts them on the cutting edge of liquid packaging.

Tom Ullmer is the Director of Engineering for Matrix

Subscribe to our email list for the latest in flexible packaging news.