By Spencer Johnson

Nutraceuticals are a booming business that show no signs of slowing down.

In the U.S. alone, the nutraceutical market was valued at $167 billion last year, with a projected growth rate of 6.2% through 2030, according to market research firm Grand View Research. The category is just as popular overseas as well, driving a staggering $591 billion industry globally, with similar growth patterns projected in the coming years, the market research firm concluded.

While nutraceuticals, a food-derived product category that provides health benefits beyond basic nutrition, comes in many varieties, powder is generally the most common formulation. Electrolytes, hunger control, and protein are typical examples of nutraceuticals – many of which are brought to market via co-manufacturers.

This is a common route for nutraceutical brands, especially start-ups that may not have the resources to invest in manufacturing and packaging. In addition to cost savings, co-manufacturers bring flexibility and speed to market to brands looking to launch a new product or expand production. And playing a key role in this mutually beneficial relationship is INVpack.

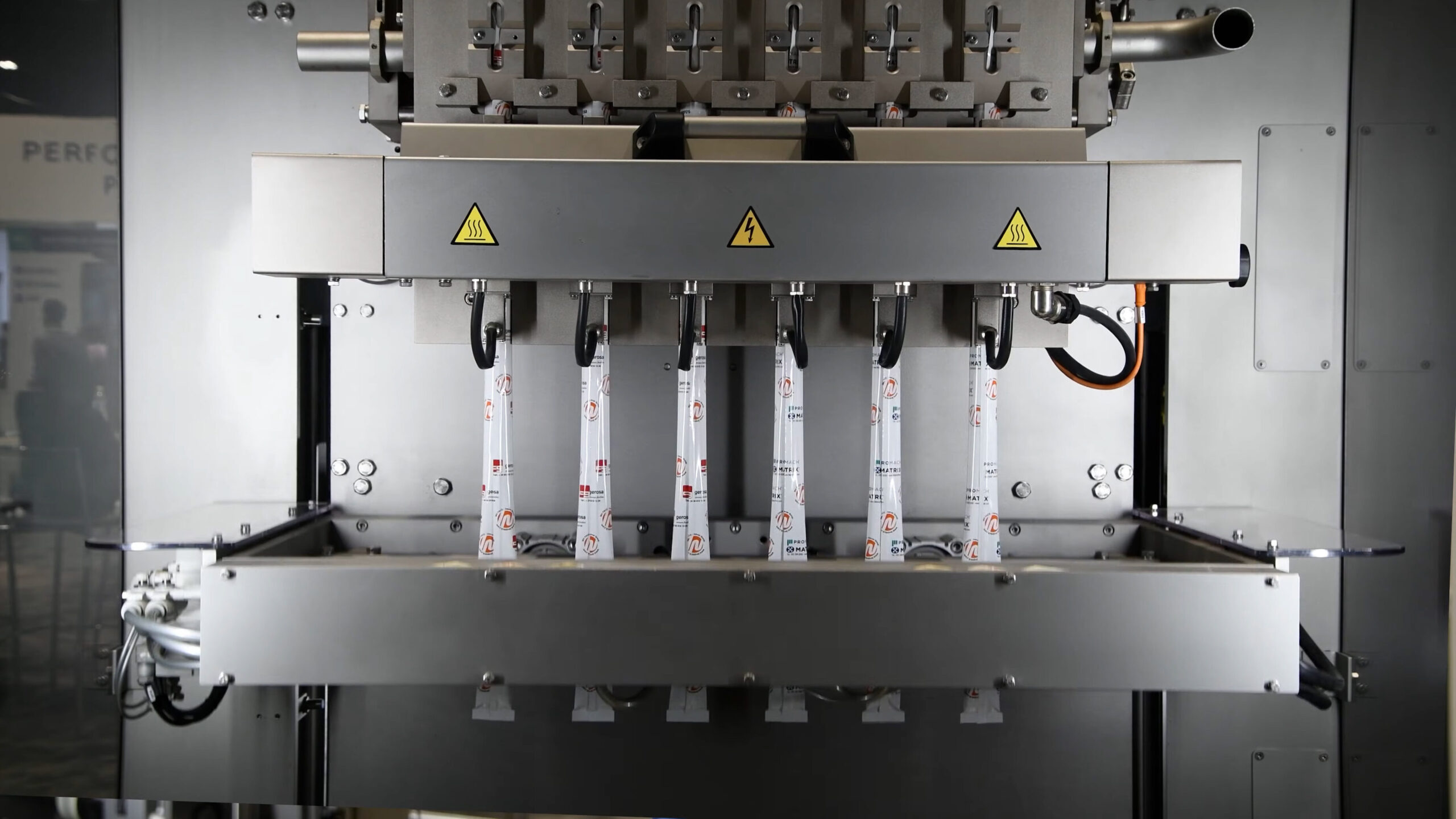

The advantage INVpack brings to co-manufacturers working with nutraceutical brands is accuracy, versatility, ease of use, and machine access.

Accuracy is one of the biggest benefits of an INVpack stickpack or sachet machine. We worked with a nutraceutical brand that had struggled with over filling. The solution was to replace a competitor’s stickpack machine and check weigher with an INVpack unit. The precision of INVpack not only eliminated the need for a check weigher, but simplified the line and saved them money in the long run through accurate fills. The brand has since added more than 10 INVpack machines to its packaging lines.

Co-manufacturers often run several different SKUs, which require multiple changeovers. INVpack gives customers peace of mind in knowing our machines are versatile to run a wide range of formulations today, as well as any emerging trends of tomorrow.

Simplicity and machine access are hallmarks of INVpack machines, especially in the filling area. A more streamlined design makes it easier for a more diverse workforce to operate the line, as well as perform changeovers and clean the machine.

The other intangible benefit INVpack can bring to co-manufacturers is complete project management. Matrix, a ProMach brand and the North American master distributor of INVpack, is part of a global family of over 50 product brands that operate across every point of the production line. The advantage this brings to co-manufacturers is the ability for INVpack/Matrix to look beyond just the stickpack or sachet machine to identify other areas where upgrades can be made to improve speed and efficiency.

For example, if you’re running stickpacks, performing a count, putting them into a pre-made pouch or carton, loading into a case, and building a pallet for shipping, automated solutions for each function can all be sourced from other ProMach brands. It’s truly a one-stop shopping experience where we take the lead on project management and integration.

Accuracy, versatility, ease of use, and machine access are factors co-manufacturers that run nutraceuticals look for in packaging equipment. INVpack is built with those four must-haves in mind. When you are ready to discover the advantages INVpack brings to your next nutraceutical processing and packaging line, we’re ready to help!

Spencer Johnson is the Western Regional Sales Director for ProMach’s Flexible Packaging Group. He can be reached at spencer.johnson@promachbuilt.com.

Subscribe to our email list for the latest in flexible packaging news.