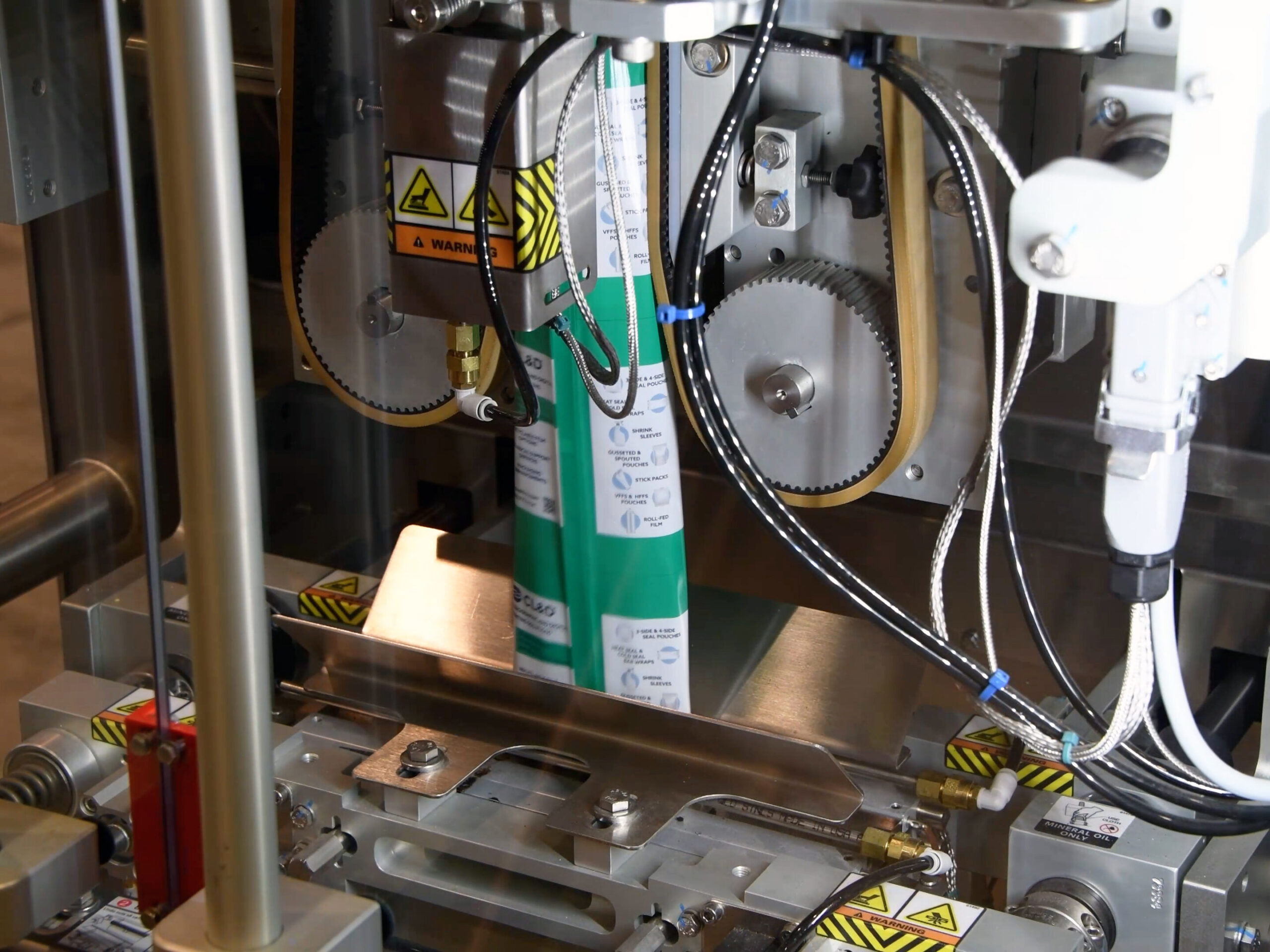

How to recognize the signs—and why a cost-effective, American-made solution might be your best next step

Every packaging machine has a lifespan. But for many small to mid-sized companies, it’s tempting to keep an old machine running as long as possible, even if it’s become slow, inconsistent, or frustrating to maintain.

Here’s the problem: there comes a tipping point where repair costs, lost production, and inefficiencies outweigh the savings of “just keeping it going.”

5 Signs Your VFFS Machine May Be Past Its Prime

- Electrical or mechanical components are obsolete

If you’re struggling to find replacement parts—or your techs are using creative workarounds—it may be time to reevaluate. - Downtime is eating into your output

Unexpected maintenance is more than an inconvenience—it directly impacts your bottom line. - Sealing inconsistencies or bag quality issues

Over time, even minor alignment issues or worn jaws can lead to product waste or unhappy customers. - Labor or support challenges

If new operators can’t be trained easily, or if the machine lacks modern controls, you’re losing operational efficiency. - You’ve outgrown its capabilities

Even if your old machine still technically runs, it might not meet the current demand for speed, compliance, or consistency.

What to Consider in a Replacement

When you’re ready to explore a new solution, consider a machine that’s:

- Simplified for everyday use

- Built with updated, supported electronics

- Backed by proven field performance

- American-made for quick parts access and reliable service

- Designed to handle just what you need—no unnecessary extras

There are now vertical baggers on the market specifically designed to replace older machines at the end of their lifecycle—often using the same footprint and offering commonality in parts, making the transition smoother and more affordable.

A Better Long-Term Investment

Rather than continuing to invest in stopgap repairs, upgrading to a modern, entry-level bagger can restore peace of mind while giving your operation a performance boost.

Curious what your replacement options look like? We’re here to help you evaluate whether repair, retrofit, or a new machine makes the most sense for your goals and budget.

Subscribe to our email list for the latest in flexible packaging news.