By Richard Carlton

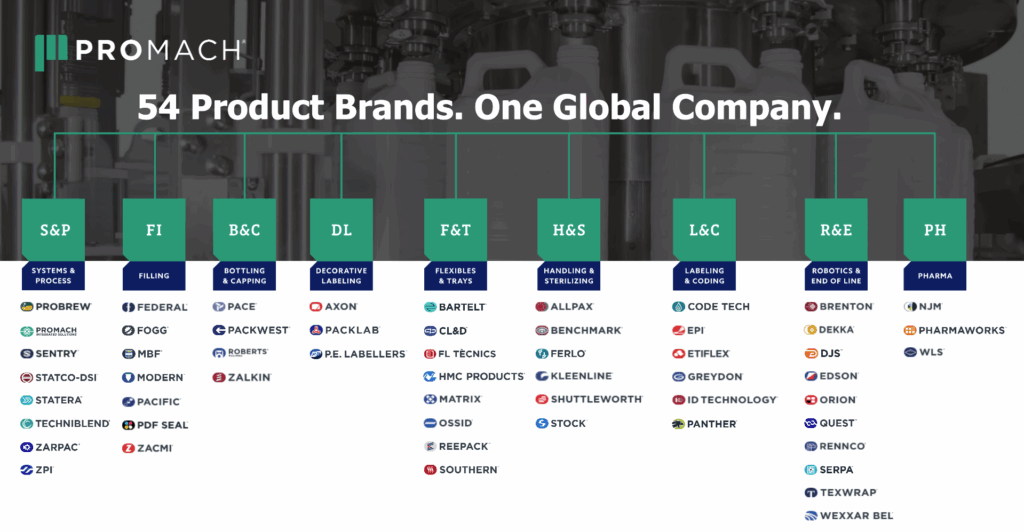

The Power of ProMach is a phrase we often use to describe the synergies created among our more than 50 product brands across nine business lines. ProMach brands encompass the entire packaging spectrum covering areas such as Filling & Capping, Pharmaceutical, Robotics & End of Line, and Flexibles & Trays, which includes Matrix, Bartelt, Ossid, and other related brands.

To me, what the Power of ProMach means is the ability to leverage the expertise of all our product brands to create a customized solution for customers. The value of this business model for customers is immense. Not only can we tap into the collective resources of our brands, but we also consolidate project management from start to finish, giving the customer one central point of contact.

A few recent examples highlight the Power of ProMach in action. One involved a candy manufacturer in the early stages of plant expansion. Their existing processes were largely labor-intensive, with employees building and hand-packing cases, as well as manually stacking products onto pallets. We asked the management team if they planned to stay the course with manual operations, or if they were open to exploring how automation could be applied to the entire production line. Not surprisingly, they were interested in automating the whole line, and were excited to be involved in a partnership that would help them realize that goal.

In another case, a frozen food manufacturer needed to place multiple products into a single package for sale at club stores. While their operations were already automated for single package applications, they were not properly set up to efficiently support this new demand.

In both cases, we leveraged the capabilities of multiple ProMach brands to design a customized solution that optimized the business’s packaging setup from end to end.

For the candy manufacturer, we divided this project into two phases to concur with its expansion plans. Our solution included a Matrix vertical form fill seal machine and a premade pouch machine from Pacraft, a brand for which Matrix serves as the North American master distributor. To automate the downstream packaging operations, which included metal detection, check weighing, robotic case packing and palletizing, we brought in Quest, a leading brand from ProMach’s Robotics & End of Line business line.

Likewise, the solution for the club store customer, which featured an automated cartoner, case erector, and labeler, was a collaboration between Bartelt and ID Technology, a brand from ProMach’s Labeling & Coding business line.

Customers like these rely on ProMach because we offer the most up-to-date technologies for their packaging operations. We’re subject-matter experts with the resources of more than 50 ProMach brands to us to create the best possible solution for their application.

At its core, the Power of ProMach is about the ability to take the lead on any packaging project. Our business model gives customers with one point of contact who understands the entire packaging process and can provide strategic recommendations to enhance operations. Many customers today do not have the bandwidth to research and source each component on their line or assume project management responsibilities.

On the other hand, what customers do have is a vision for their packaging operations and how those operations fit into their long-term organizational goals. Working with the right manufacturer can unlock the steps to realize that potential, and when combined with the technical capabilities of the more than 50 product brands, we can bring their vision to life.

That’s the Power of ProMach.

Richard Carlton is a Regional Sales Manager with ProMach’s Flexible Packaging Group. He can be reached at Richard.Carlton@ProMachBuilt.com.

The Flexible Packaging Group includes Matrix, Bartelt Packaging, HMC Products, and FLtècnics.

Subscribe to our email list for the latest in flexible packaging news.