Forrest Gump once said, “Life is like a box of chocolates. You never know what you’re gonna get.”

That analogy symbolizes the unpredictability of life. But for candy manufacturers, unpredictability is the last thing anyone wants, especially in their packaging operations. With so many different options to package candy, choosing the right system for a particular product can be a bit of a gamble… much like picking the right chocolate from a box. Fortunately, manufacturers can minimize that risk by working closely with a reputable packaging OEM that can provide guidance toward a solution that adds reliability and efficiency to your operation.

There is no doubt that Americans love their candy. According to the National Confectioners Association, the U.S. candy market is a $35 billion industry. That’s a staggering number of sweets – all of which need to be packaged. Two of the most effective methods are vertical or horizontal form fill seal packaging. Each has its strengths depending on the applications.

Vertical Form Fill Seal

Vertical form fill seal (VFFS) machines create bags by pulling roll stock film above and around a forming tube. The film is sealed and the pouches are filled at high rates, up to 200 bags per minute – all within a compact footprint. These machines can create a variety of package styles popular with candy manufacturers and confectioners, including pillow, quad, gusset, flat bottom, and others.

Horizontal Form Fill Seal

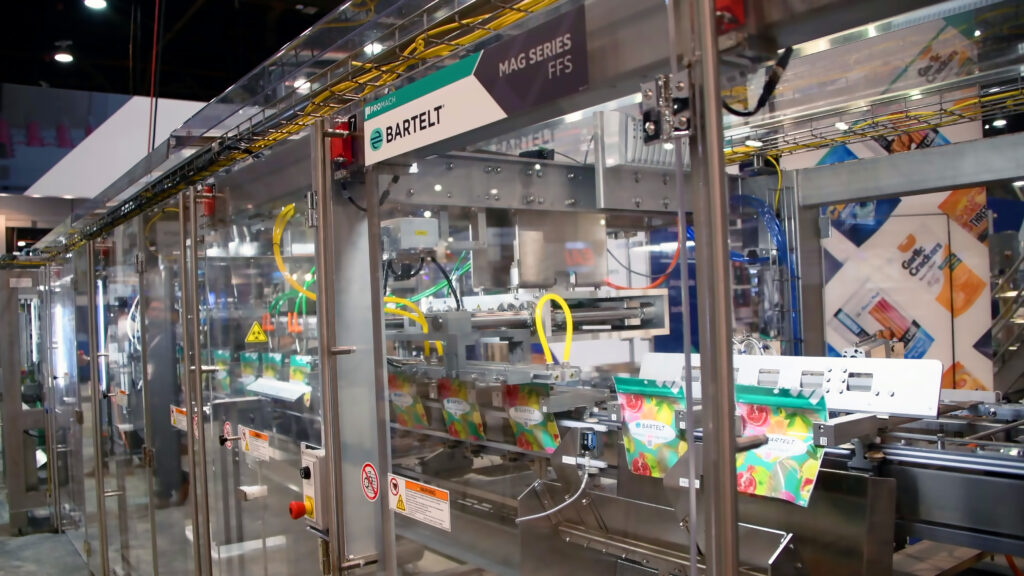

Horizontal form fill seal (HFFS) machines manufacture and fill pouches in a step-by-step process that supports a variety of pouch types and shapes such as standup, three-sided, and four-sided pouches, along with various closure options, like zipper or other fitments. Typical fill rates are around 150 pouches per minute, but speeds can reach up to 300 per minute, depending on the application.

The Case for Vertical Form Fill Seal

VFFS machines are ideal for small candies, as well as granular or powdery sweets. Common products include pre-wrapped candies, hard candy mixes, chocolate covered nuts and cherries, and more. Well-built VFFS machines preserve product integrity across a range of formats, from single use to family-size and bulk options, including bag-in-bag, which is popular with club store retailers.

One big advantage of VFFS is its compact design, making it a strong solution for when floor or overhead space are tight.

They are also extremely flexible, with changeovers taking just minutes, an attractive feature to candy co-packers handling several SKUs in a shift. The ability to quickly pivot both packaging styles and candy is at the core of many co-packers’ business model.

This flexibility and compact design makes VFFS a smart choice for small- to medium-sized candy manufacturers and confectioners running short batches of various products.

The Case for Horizonal Form Fill Seal

While VFFS machines are known for their flexibility and compact design, HFFS machines stand out for their speed and the ability to produce eye-catching pouches.

HFFS machines are ideal for large manufacturers focused on consistent, high-volume production due to their ability to reach high processing speeds. Though these machines do require more space, the speeds and output they produce make the tradeoff worthwhile.

HFFS can also accommodate a wide range of packaging styles with sharp, high-quality graphics that stand out on shelves. A crisp, wrinkle-free pouch not only enhances visual appeal, but it can serve as a competitive advantage. A package’s appearance can influence shelf placement and even determine whether a retailer stocks the product at all.

HFFS machines also offer more flexibility than many realize. These machines can run multiple formats, giving customers the flexibility to run different sizes and styles of packaging. The level of flexibility in horizontal solutions is something that many confectioners are unaware of, an unexpected feature that gives them an advantage in the marketplace.

Getting Started

Finding the best machine for your application starts with a packaging OEM supplier that understands the full scope of your project so they can serve as a trusted adviser in recommending the optimal solution. Below is a partial list of questions that can help guide them in developing a recommendation aligned with your goals and objectives.

- What are your short- and long-term goals for this line?

- What is the available ceiling and floor space for the machine?

- What is the product being filled and how will it be fed?

- What are the flow characteristics?

- What type(s) of film will be used?

- What is the speed of every piece of equipment before and after the bagger or poucher?

- How is the product arriving at the packaging machinery, and how is it exiting?

- What are the bag/pouch sizes and styles you expect to run?

- What is the desired fill rate per minute and target product weight?

- Will there be many changeovers or SKUs?

- How does the machinery integrate into your existing equipment?

- What is the budget and the timeline for this project?

Wrapping It Up

From single-serve gummy pouches to giant Halloween variety packs, the impact of VFFS and HFFS machines are everywhere in the candy industry. But ultimately, the proof is in the pudding. These machines are not a one-size-fits-all solution. Manufacturers should carefully evaluate the benefits of adding automation and the factors that influence machine specifications. Partnering with an expert OEM for strategic guidance and post-purchase support can help ensure the process is a piece of cake.

Richard Carlton is a Regional Sales Manager for the Flexible Packaging Group at ProMach (https://www.matrixpm.com/). You can reach him at richard.carlton@promachbuilt.com. Lou Pelnar is a Regional Sales Manager for the Flexible Packaging Group at ProMach (https://www.barteltpackaging.com/). You can reach him at lou.pelnar@promachbuilt.com.

Subscribe to our email list for the latest in flexible packaging news.

Bartelt and Matrix, both ProMach brands, have combined their sales teams to create a seamless experience for customers exploring either a vertical or horizontal flexible packaging solution. This new team, the Flexible Packaging Group, enables sales representatives to consultatively sell the best solution from both Bartelt and Matrix as a single point of contact for customers to provide a more efficient purchasing experience.